Kesar Control Systems

Photostability Chamber

Introduction

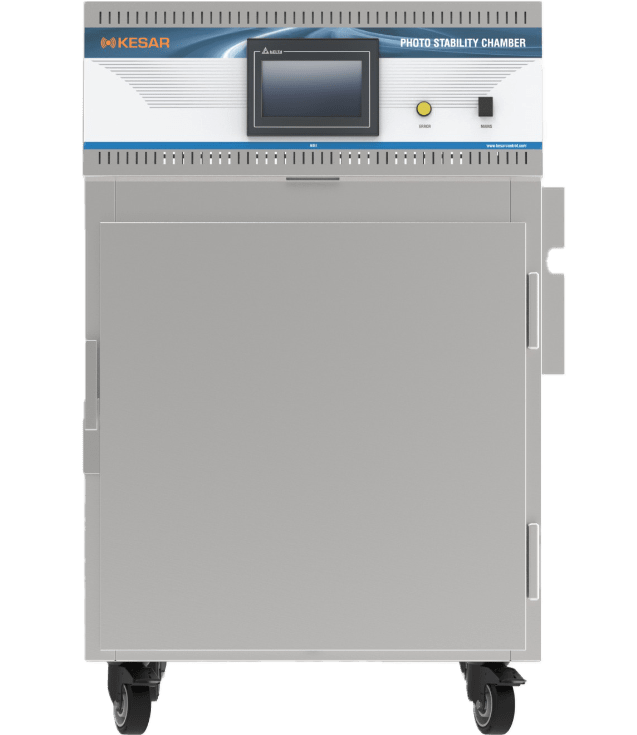

Kesar Control System’s, a leading pharmaceutical and laboratory equipment manufacturer, offers Photostability Chambers designed for controlled light and temperature testing of pharmaceutical, cosmetic, and industrial products. These chambers ensure compliance with ICH Q1B guidelines, making them essential for stability testing under simulated daylight conditions.

A Photostability Chamber is a specialized environmental chamber used to test the effects of UV and LUX light exposure using in Laboratories, Chemicals, Life Science, Government Institutes, and Cosmetics etc. By simulating natural and artificial light conditions, these chambers help manufacturers assess the stability, degradation, and shelf life of products exposed to prolonged illumination.

Kesar Control System’s Photostability Chambers provide precise temperature, humidity, and light control (UV & LUX), ensuring accurate and repeatable results for regulatory compliance and quality assurance.

Construction

- Constructed and fabricated on fully automatic CNC machines.

- Chamber interior is designed with dull or mirror finish stainless steel.

- Fluorescent Tubes for daylight effect and UV tubes for ultraviolet ray in accordance with the ICH guidelines.

- External finish manufactured with Stainless Steel for GMP model and G.I powder coated for the standard model.

- The internal of the chamber is water and vapor tight with High Grade stainless steel.

- Seams are arc-welded for strength & durability.

- Chambers are regulated with air circulation, heating & cooling, Uv & Lux Light, humidity generator system.

- Double Door system with outer door insulation. The inner Glass door offers full internal visibility. Doors sealed with silicone gasket along with Lock & key feature.

- Easily accessible Control Panel with electrical switchgear & refrigeration mounted on top.

- Mounted on heavy castor wheels for easy movement.

- Adjustable Stainless Steel electro polished Perforated/wire mesh type trays also easy to clean.

Technical Specification

| Temperature Range | 20°C to 60°C |

|---|---|

| Accuracy | ±1.0°C |

| Uniformity | ±2.0°C |

| Control System | PLC Based |

Sizes

| Models | Capacity | Dimensions (W X D X H) | Nos. of Light Bank | |

|---|---|---|---|---|

| Internal Width X Depth X Height (mm) |

External Width X Depth X Height (mm) |

|||

| KGOP-227 | 227 LTR | 600 X 630 X 600 | 790 X 1070 X 1210 | 1 |

| KGOP-325 | 325 LTR | 600 X 630 X 900 | 790 X 1070 X 1510 | 2 |

| KGOP-400 | 400 LTR | 600 X 630 X 1060 | 790 X 1070 X 1670 | 2 |

Other Details

Specifications

Kesar Control System’s Photostability Chamber is designed to provide precise and controlled light exposure for stability testing in Pharmaceutical, Cosmetic and research applications. With a durable stainless steel construction and an advanced insulation system, it ensures a stable testing environment to prevent the external interference. The chamber features a user-friendly interface, allowing effortless adjustments to UV & LUX light intensity, temperature, and humidity, making it a reliable solution for maintaining product integrity under various conditions.

We Kesar - Engineered with automation and safety in mind, the Photostability Chamber includes programmable controls, automatic light regulation, and built-in alarms to alert users of any deviations. Its UV-protected viewing door allows safe observations without disrupting ongoing tests. Offering efficiency, accuracy, and ease of operation, this chamber ensures compliance with industry standards while simplifying Photo stability studies for professionals.

Control Systems

HMI/PLC ensures precise regulation of temperature, humidity, and UV and LUX light exposure for stable environmental conditions.

A display (HMI) provides real-time monitoring of temperature, humidity, and UV and LUX light intensity, ensuring accurate control.

An automatic light control system adjusts UV and LUX light exposure according to pre-set parameters for consistent testing conditions.

Alarms and safety features alert users for temperature or humidity deviations, door openings, and power failures to ensure sample protection.

USB and Ethernet connectivity enable real-time data logging and remote monitoring to ensure compliance and accurate tracking of test conditions.

Designed for energy efficiency and uniform light distribution, the chamber prevents localized heating and maintains accurate stability conditions.

Get Solution

Contact Kesar Control today to learn more about their Products and get a quote.

Contact NowDownload Catalogue

Features

- As per ICH-Q1B Guideline for Confirmatory studies, sample should be exposed to light providing an overall illumination of not less than 1.2 million lux per hours and an integrated near ultraviolet energy of not less than 200 watt hour/square meter to allow direct comparison to be made between drug substance & drug product.

- Online and actual study of UV & LUX Exposure.

- Automatic cycle cutoff after complete the study and test of UV & LUX.

- As a reputable Photostability chamber manufacturer, we engineered these chambers to provide controlled conditions for exposing samples to various light sources and simulating different climatic conditions. Our precision-crafted Photostability chambers ensure accurate and reproducible testing environments, meeting the stringent requirements of the pharmaceutical industry.

Optional Features

- Software (21 CFR PART-11 Compliance).

- Stand by Cooling System.

- Stand by Humidity System.

- Scanner (4 Temp. +4 RH for Online Monitoring Purpose).

- GSM Alert System.

- Security Alarm System.

- Extra Tray.

Hmi + Plc Controller Based

- 7″ HMI with TFT LCD Colour touch screen with password protection for all parameter actual status monitoring of utilities like Sensor, Heating & Cooling System, and Humidity System).

- Rotronic make 4-20mA sensors for better accuracy.

- PLC with auto tuning facility for accurate control of temperature and humidity conditions.

- PLC system for an auto changeover of standby systems.

- Data Storage unit facility to transfer the data to software via Ethernet for web based online remote monitoring with Date, Time, SV, PV, Door Open/ Close, Power On/Off remarks. Also transfer the data through USB.

- UV & LUX meter for Reading Recording.

- Safety/Alert: Temperature & Humidity High / Low alarm, Temperature & Humidity High / Low cut off, Low water level cut off, Auto change over for standby systems.